CFRP

Mold Material for CFRP

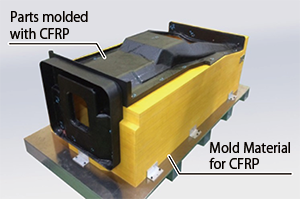

When carbon fiber reinforced plastic (CFRP) composites used thermosetting resin are formed, a mold material resistant to thermoforming in an autoclave is required.

JIC’s mold material has the following features to respond to users’ needs.

- It can withstand heating in an autoclave.

- The material has a fine texture, realizing good workability for manufacturing of complex shapes of CFRP products.

- This product has followability, making it hard to crack.

- The maximum size is t50 x 1020 x 3080 [mm] and precut materials are available for your desired size.

■Standard performance (at ordinary temperatures)

Physical property |

Test standard, etc. |

Unit |

Standard value

|

Apparent density |

JIS A 5430 |

g/cm3 |

0.5 or more but less than 0.6 |

Water content |

JIS A 5430 |

% |

5 or less |

Interlayer strength |

JIS A 5538 |

N/mm2 |

0.5 or more |

▲ Example of CFRP molded products

■Reference performance (Note 1)

Physical property |

Test standard, etc. |

Unit |

Measured value |

Heat resistance |

- |

℃ |

130 |

Coefficient of

thermal expansion |

Longitudinal

direction |

(Note 2) |

(1/K)×10-6 |

5.4 - 6.0 |

Compressive strength |

JIS A 9510 |

N/mm2 |

4.4 - 4.9 |

Flexural strength |

JIS A 5430 |

N/mm2 |

9.6 - 10.6 |

▲ Racing car equipped with parts molded with CFRP

(Note 1) These tests were carried out under procedures in accordance with the stated standard, in a similar way to the test standard or with the use of the test standard.

(Note 2) The cycle composed of heating (2℃/min), holding (130℃ for 3hrs.) and cooling (2℃/min to 50℃) was repeated three times with a thermomechanical analyzer (TMA-8310).

■Example of manufacturing procedure of CFRP molded product used mold material for CFRP

Mold making

1. Laminate to make a rectangular parallelepiped

The mold material for CFRP (standard thickness 50 mm) is laminated and bonded to produce a large laminate rectangular.

2. Processing the laminated mold material

The 5-axis molding machine cuts the laminated mold material to form a mold. Grind and shape as needed.

3. Surface treatment of mold material

An impregnated coating agent is applied to the surface of the mold. Polish as necessary to condition the surface.

→Complete the mold

Production of CFRP molded products

4. Pasting prepreg

The mold release agent is applied to the surface of the mold, and a prepreg (a resin sheet containing carbon fibers) is attached to the mold.

5. Heating in an autoclave

The mold with prepreg is placed in an autoclave and heated to cure the prepreg.

6. Removing from the mold

Remove CFRP (cured prepreg) from the mold.

→Complete CFRP molded products