About Hydrolysis

- Top

- About Hydrolysis

- Flowsheet

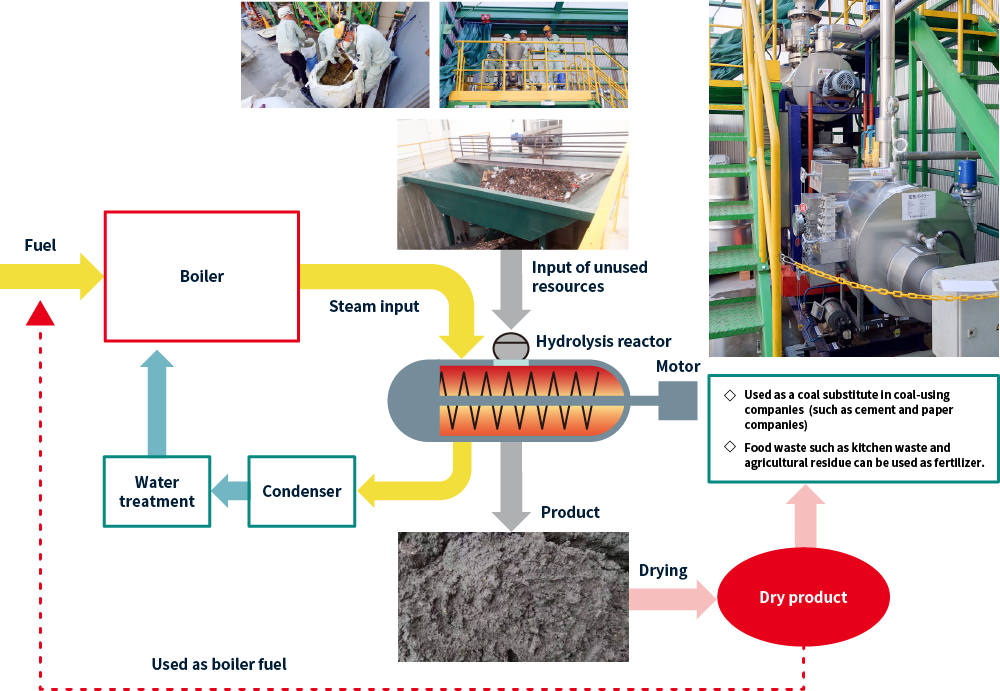

Flowsheet

- ①input hopper

- Waste is fed in and a fixed quantity is discharged by a sorting conveyor.

- ②sorting conveyor

- Remove inorganic materials (iron, stone, glass, etc.) from waste.

- ③stacker

- Temporary storage hopper for waste after sorting

- ④input conveyor

- After sorting, the waste is fed into the hydrolysis unit.

- ⑤hydrolysis equipment

- Hydrolysis processing

- ⑥discharge screw conveyor

- product discharge

- ⑦biomass boilers

- High-temperature, high-pressure steam is produced using the dried product as fuel. Steam is supplied to hydrolysis units.

- ⑧degassing tank

- After processing, high-temperature and high-pressure steam is discharged from the hydrolysis unit.

The system is equipped with functions for noise suppression, pressure reduction, and odor mitigation.

Detailed Diagram of Hydrolysis Equipment

Contact

Do you pay to have your waste treated?

Are you interested in hydrolysis and oilification reduction?